CFC Fixtures

CFC composite, due to its superior material properties, has been extremely appreciated in the high-temperature industry over the past several years. Carbon-fiber reinforced carbon (C/C) fixtures are an increasingly common choice in heat treating for several reasons:

CFC has a low weight.

One of the major advantages of CFC / CFRC is that the material is much lighter than steel - by as much as 1/5 its weight. This makes it possible to produce lighter fixtures, and such a savings is huge because of the cost of the brazing operation. Each kilogram requires a lot of heat to bring it up to brazing temperature, and it not only costs a lot more, but each additional weight makes the entire brazing cycle take longer. This results in an even higher cost that must be taken into account. Importantly - reduced weight does not mean reduced strength, because CFC composite at high temperatures, compared to metals, is much stronger. An additional advantage is the ability to increase the yield of heat treatment products.

C/C composite reduces operating costs.

Some people disregard CFC as an alternative because of its cost. On the other hand, with a deeper analysis of its use, significant cost savings can actually be achieved. C/C composite has excellent thermal conductivity properties, which allows for shorter heating and cooling times, thus reducing energy consumption. In addition, its durability and low maintenance cost means that overall operating costs are reduced. Investing in fixtures made of CFC is an essential way to reduce the long-term operating costs of a vacuum furnace.

CFC is an extremely strong material.

The carbon fiber composite is a lightweight but very strong product - its mechanical strength increases with increasing temperature. Due to its high resistance to thermal shock, CFC fixture is very stable and maintains its shape, unlike metal parts which warp and crack with prolonged use. If oxygen is not available in the vacuum furnace, CFC can last for several years on average, thus increasing productivity and reducing costs, maintenance and downtime. In addition, due to the lower weight of CFC, production efficiency can be increased because it allows more parts to be loaded into the furnace and more profit can be made per batch.

CGT Carbon GmbH offers fixtures acc. to supplied technical documentation, but we also offer designing furnace fixtures specially for you, based on your requirements.

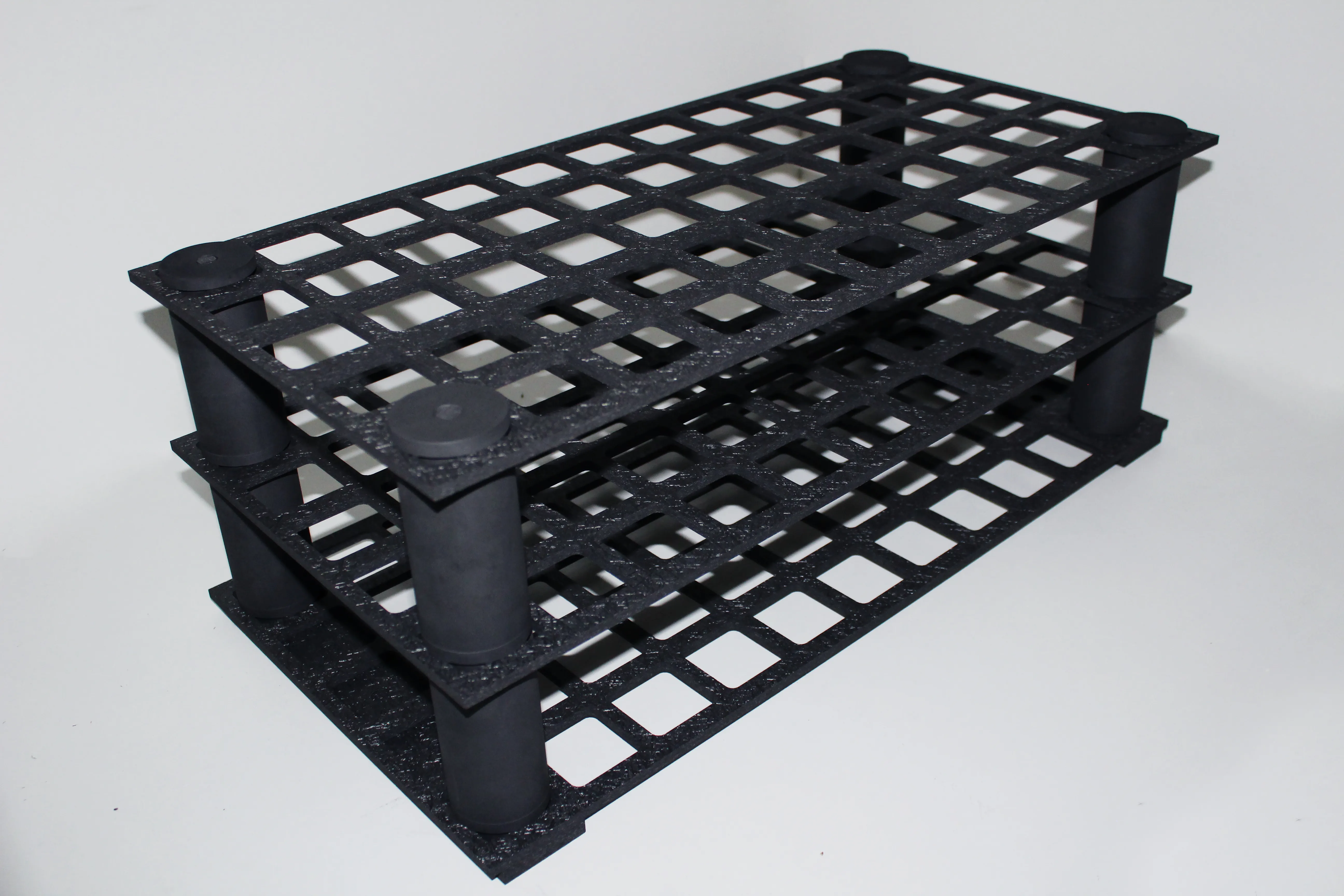

We can supply you the following:

- CFC trays

- CFC shelves

- CFC plates for brazing

- CFC racks

- CFC grids

- CFC hole plates

- CFC screws

- CFC threaded rods

- CFC nuts

and many other components.

Our extensive experience and in-house design background is at your disposal - we will be glad to help you reduce your furnace operating costs. For more information - contact us.