CFC Material

Carbon composites, CFC, C/C

These are common terms for carbon fiber reinforced composites. They combine the unique properties of the Carbon element - especially high resistance to heat and chemical corrosion resistance - and the physical properties of carbon fibers, which give the final product extremely high strength and flexibility.

It is a highly advanced material, produced from carbon fibers, which are laid up in layers to form a carbon fiber matrix. Composites enable the production of components with excellent heat resistance, low weight and high strength. They are ideal for high temperature environments and the heat treatment industry.

The use of CFC materials leads to energy savings, increased efficiency and an overall reduction in operating costs.

What is a C/C composite material?

It's one of the most advanced engineering material. Significantly improved materials by making a composite of different materials.

| Composite | Reinforced Material | Matrix |

|---|---|---|

| C/C Composite | Carbon Fiber | Carbon |

| Graphite | None | Carbon |

| CFRP | Carbon Fiber | Resin |

| GFRP | Glass Fiber | Resin |

| Reinforced Concrete | Metal Rebar | Cement |

Characterictics of CFC Composite

- high heat resistance (no reduction in strength under high heat)

- light weight (density 1.7g/cm³)

- low thermal expansion (greater stability in relation to size)

- high heat shock resistance (under extreme temperature change)

- excellent sliding characteristics

- high resistance to corrosion

- ability to control electrical conductivity / thermal conductivity

Anti-Corrosion Stainless, Titanium and C/C Composite Comparison

| Chemical | C/C | Anticorrosion stainless | Titanium |

|---|---|---|---|

| Hydrochloric Acid (27 / 77 °C) | O | X | X |

| Dilute Sulfuric Acid | O | X | X |

| Concentrated Sulphuric Acid | X | X | X |

| Nitric Acid | X | O | O |

| Phosphoric Acid | O | O | X |

| Sodium Hydroxide | O | O | O |

| Ammonia | O | O | O |

| Sodium Carbonate | O | O | X |

O = resisted

X = corroded

Applications of carbon composite

| Category | Application |

|---|---|

| Heat Resistance: | Furnace Parts |

| Trays and Jigs | |

| Springs | |

| Heating Elements | |

| Aerospace Parts | |

| Sliding and Friction: | Brake Materials |

| Clutch Plates | |

| Sliding Boards for Pantograph | |

| Industrial Bearing | |

| Advanced Material: | Solar Cell Manufacturing Equipments |

| Chemical Manufacturing | |

| Semiconductor / Display Manufacturing Equipments |

CFC Threaded rods and nuts

C/C-composite Bolts & Nuts characterized by its high heat resistance are used in many high temperature environments over 1000°C while metals or ceramics lose mechanical strength.

Also, the unique graphite properties such as resistance to adhesion or friction make them ideal for joining components under high temperatures.

| Sorts | Max. Length (mm) | Standard Square Nuts |

|---|---|---|

| M6 | 1000 | 14 x 14 x 5 |

| M8 | 1000 | 16 x 16 x 5 |

| M10 | 1000 | 20 x 20 x 10 |

| M12 | 1000 | 22 x 22 x 10 |

| M16 | 1000 | 26 x 26 x 10 |

| M20 | 1000 | 32 x 32 x 20 |

C/C Coil Spring

Springs made of C/C composite are characterized by their excellent heat resistance and maintains the spring properties during repeated use at high temperatures.

| Type-A | Type-B | Type-C | Type-D | |

|---|---|---|---|---|

| Ø Outside diameter (mm) | ȹ 31 | ȹ 50 | ȹ 50 | ȹ 50 |

| Ø Inside diameter (mm) | ȹ 19 | ȹ 20 | ȹ 30 | ȹ 20 |

| Length (mm) | L40 | L25 | L27,5 | L40 |

| Spring constant (kgf/mm) | 2 | 2 | 2,5 | 3,5 |

| Max. contraction (mm) | 7 | 5 | 5 | 7 |

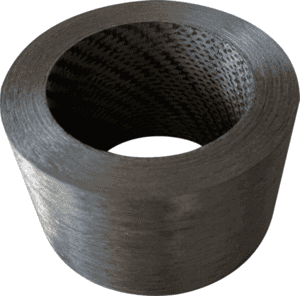

CFC Cylinders

CGT Carbon delivers CFC cylinders up to a diameter of Ø1500mm in an excellent quality for high temperature applications such as hot pressing of tungsten carbide or ceramics.

For more information about our CFC grades, please don’t hesitate to contact us. Our engineers will be glad to answer all your questions and provide you with the necessary information.