Titanium Carbide Coating

Titanium Carbide Coating (TiC3) is a very high temperature (3100°C) corrosion resistant coating (+1000°C beyond SiC3 in high vacuum environment).

CGT Carbon GmbH has developed a high purity dense titanium carbide (TiC) coating to protect graphite and refractory metals in high temperature vacuum environments. With vapour pressures 3 orders less for TiC when compared to SiC the material goes beyond our SiC3 in protection in vacuum and other high temperature environments.

Highlights

- Protect graphite close to melting point of TiC3 (3100°C).

- Vapour pressure >2200°C in 10e-8 Torr.

- Cubic structure giving high density and isotropic properties.

- Highly Electrically Conductive at Room Temperature.

- Excellent corrosion resistance.

- Extremely hard.

- High purity less than 125ppm total: (Cl - 48ppm, Si - 45ppm, Ni - 9.5ppm, S - 8.8ppm).

- Semiconductor super-high purity less than 10ppm total.

- Crystal size adjustable between 2 – 100 μm.

- Coating thickness: 10 – 100 μm.

- High growth rate for cost effectiveness.

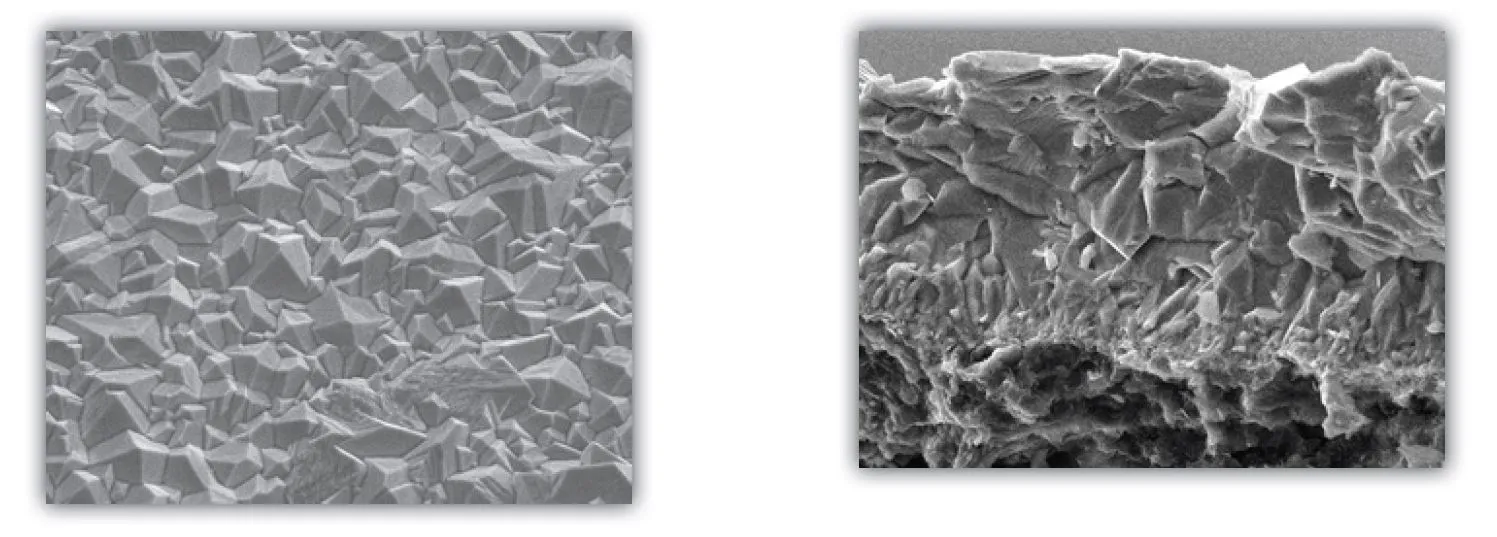

SEM

Surface and fracture as observed with Scanning Electron Microscope are shown below.

Penetration

The porosity of graphite is covered very well and the coating penetrates the open porosity and enhances a very good adherence of the coating on the graphite surface. Adherence on sharp edges is good but in all cases a radius of at least 0.2 mm is advised.

Applications

- semiconductor industry

- aerospace industry

- high temperature enviroments

- high vacuum environments

- MOCVD & Epitaxy

General Properties

| Parameter | Value |

|---|---|

| Density | 4930 kg.m-3 |

| Crystal Structure | Cubic (cF8) |

| Porosity | 0% |

| Crystal Size | 2 – 10 μm |

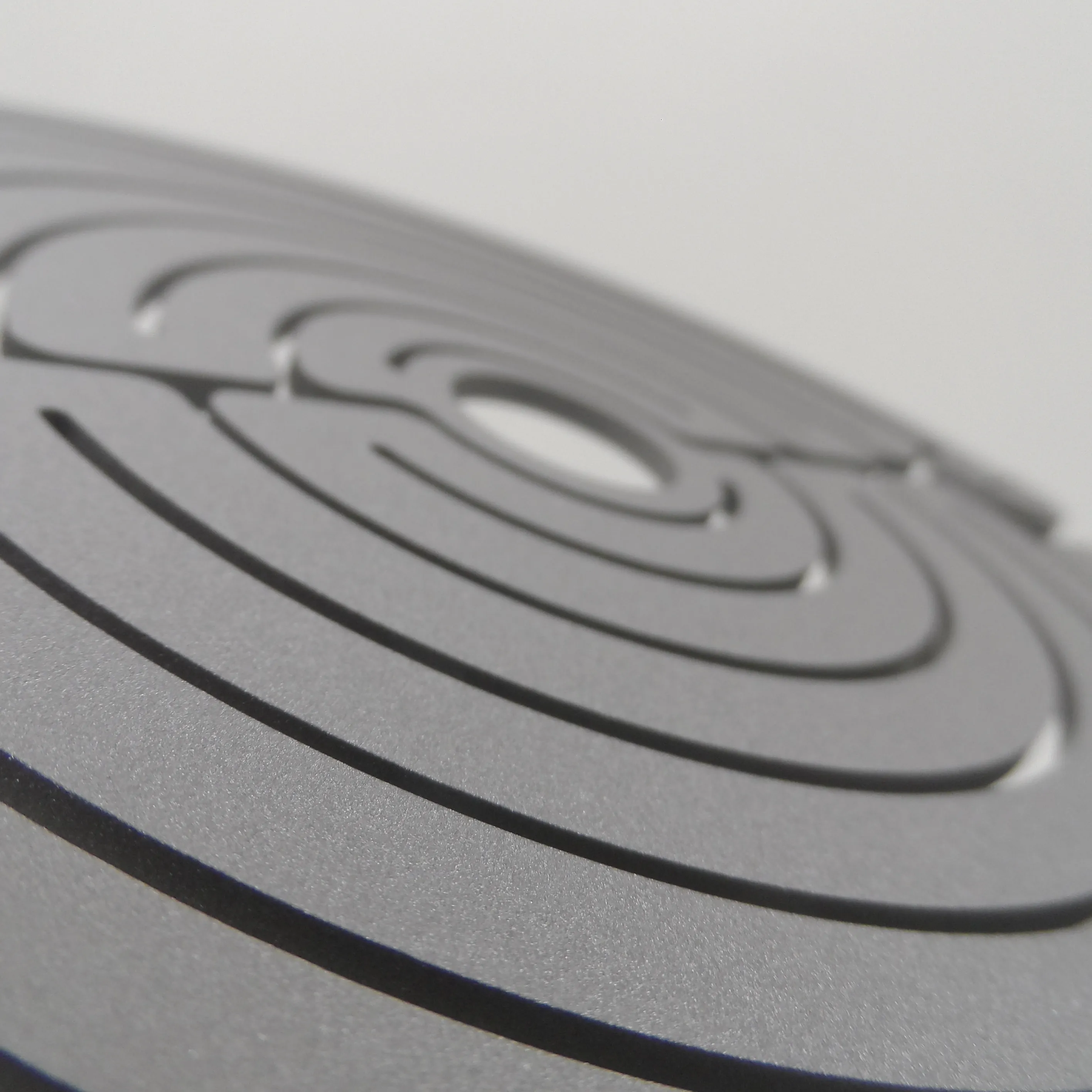

| Visual Appearance | Light Grey, Satin |

| Thermal Expansion (20 – 1500°C) | 7.7 x 10-6 m.K-1 |

| Thermal Conductivity (@ 20°C) | 50 W.m-1.K-1 |

| Elastic Modulus (@ 20°C) | 420 GPa |

| Electrical Resistivity (@ 20°C) | 0.02 Ω.m |

| Hardness (Vickers) | 3500 HV |

Listed Values are typical. Some can be tailored to applications.

The deposition process combines high growth rate, controlled crystal size, isotropic structure and low surface roughness.

The coating can be applied to parts to be used in semiconductor, aerospace and heating technologies. The combination of graphite selection and graphite machining expertise developed by CGT Carbon GmbH will ensure that customers experience optimal support for various critical components. The TiC3 is also applicable on a range of refractory materials (i.e. tungsten, molybdenum), selected ceramics and ceramic composites.

Material Purity

| Element | Concentration (PPM WT) |

|---|---|

| Na | <0.005 |

| Mg | 0.02 |

| Al | 0.24 |

| Si | 45 |

| P | 0.27 |

| S | 8.8 |

| Cl | 48 |

| K | 0.03 |

| Sn | 0.04 |

| Ba | <0.005 |

| Hf | <0.01 |

| W | <0.05 |

| Re | <0.01 |

| Pt | <0.05 |

| Ca | 5.2 |

| Cr | <0.05 |

H, C, N, O recommended by Intersitial Gas Analysis (internally equipped).

If you require more information on Titanium Carbide Cubic Coating (TiC 3), or if you would like to inquire about a quote, please don’t hesitat to contact us.